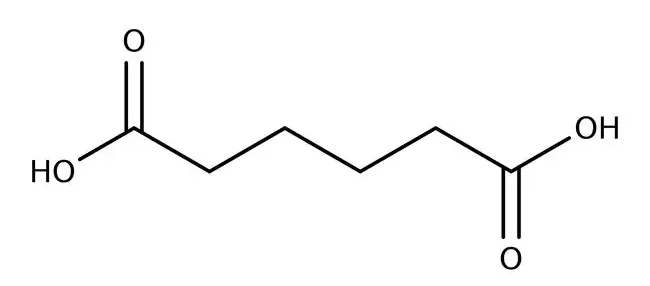

Adipic acid is a key industrial chemical, primarily used in the production of nylon, plastics, and food additives. However, traditional production methods have raised environmental concerns due to their reliance on fossil fuels and greenhouse gas emissions. In response, UP Biochemicals is exploring sustainable alternatives that not only reduce environmental impact but also align with global sustainability goals. This post will delve into the methods for producing sustainable adipic acid and the innovations driving this change.

Understanding Traditional Production Methods

Before exploring sustainable practices, it’s essential to understand how adipic acid is traditionally produced. The conventional method involves the oxidation of cyclohexane, which is derived from petroleum. This process is energy-intensive and results in significant emissions of nitrous oxide, a greenhouse gas that has a much higher warming potential than carbon dioxide.

1. Bio-Based Production Methods

One of the most promising avenues for sustainable adipic acid production is bio-based methods. This involves sourcing raw materials from renewable resources, such as plant biomass. Here’s how it works:

- Feedstock Selection: Various feedstocks, such as glucose or lignocellulosic materials (derived from wood, straw, and other plant matter), can be used. These materials are renewable and can significantly reduce reliance on fossil fuels.

- Fermentation Process: Microorganisms (like bacteria or yeast) can convert the sugars present in these feedstocks into adipic acid through fermentation. This method not only produces less carbon emissions but can also lead to a lower overall energy consumption compared to traditional methods.

- Downstream Processing: After fermentation, the adipic acid needs to be purified. Advances in bioprocessing techniques, such as membrane filtration and distillation, are being developed to make this process more efficient and environmentally friendly.

2. Green Chemistry Approaches

Implementing green chemistry principles can further enhance the sustainability of adipic acid production:

- Catalytic Processes: Utilizing catalysts to facilitate chemical reactions can minimize the energy required for production. For instance, UP Biochemicals proprietary technology transforms sugar into high-quality adipic acid, reducing CO2 emissions by over 90% compared to traditional methods. By controlling the production process, we ensure superior performance and purity, while minimizing waste and separation costs.

- Waste Minimization: Green chemistry emphasizes the reduction of hazardous substances and waste. By optimizing the production process, manufacturers can reduce by-products, making the process more sustainable.

3. Carbon Capture and Utilization (CCU)

Integrating carbon capture technologies into adipic acid production can also enhance sustainability:

- Carbon Capture: Implementing carbon capture systems in production facilities can capture CO2 emissions generated during the manufacturing process. This captured carbon can be reused in various applications, including the synthesis of adipic acid.

- Circular Economy: By reusing carbon emissions in the production process, companies can contribute to a circular economy, where waste is minimized, and resources are continually cycled through various applications.

4. Life Cycle Assessment (LCA)

Conducting a life cycle assessment is crucial in identifying the sustainability of adipic acid production methods:

- Environmental Impact: An LCA evaluates the environmental impacts of different production methods from raw material extraction to final product disposal. By comparing traditional and sustainable methods, manufacturers can make informed decisions that align with sustainability goals.

- Continuous Improvement: By regularly assessing their processes, companies can identify areas for improvement, leading to ongoing enhancements in sustainability.

Conclusion

As the demand for sustainable products grows, the production of adipic acid must evolve. By adopting bio-based methods, green chemistry principles, carbon capture technologies, and conducting life cycle assessments, the industry can produce adipic acid in a way that minimizes environmental impact.

Transitioning to sustainable adipic acid production not only helps reduce greenhouse gas emissions but also contributes to a more sustainable chemical industry. As innovations continue to emerge, the future of adipic acid production looks promising, paving the way for a greener, more sustainable world.

Adipic acid, with the chemical formula C6H10O4, is a crucial industrial chemical that plays a significant role across various sectors. From textiles to food production, adipic acid is integral to many everyday products. In this post, we will explore its diverse industrial applications and the ongoing efforts to produce it sustainably.